Automotive

Lighter, safer, more efficient: the aluminum honeycomb sandwich panel optimizes tomorrow’s vehicles.

THE ADVANTAGES OF ALUMINUM HONEYCOMB SANDWICHES FOR THE AUTOMOTIVE INDUSTRY

In the world of automotive engineering, every ounce of weight saved can make a difference in terms of performance and efficiency.

Aluminum honeycomb sandwich panels are particularly well-suited to meet the demands of this industry. Halcyon technology makes it possible to design complex-shaped parts in aluminum honeycomb sandwich.

Beyond its lightness, this material offers many other advantages:

Mass gain

The use of aluminum sandwich panels makes vehicles lighter, thus improving their energy efficiency and overall performance.

By reducing fuel consumption and CO2 emissions, this technology is perfectly in tune with the environmental challenges of our time, contributing to a more sustainable future.

Vibration absorption

The honeycomb structure of these aluminum sandwich panels offers major advantages in terms of vibration absorption, acoustic insulation and thermal stability.

Thanks to their honeycomb configuration, these panels act as real shock absorbers, absorbing vibrations and reducing unwanted resonances. As a result, components last longer. This material also provides excellent acoustic insulation, reducing road noise and enhancing passenger comfort.

Strength and rigidity

Aluminum honeycomb sandwich panels combine excellent rigidity with high load-bearing capacity. Thanks to their ability to absorb a considerable amount of energy on impact, they play a key role in improving passenger safety. This absorption property is essential for the design of body and chassis components, offering optimum protection in the event of a collision.

Recyclability

Aluminum honeycomb sandwich panels are distinguished by their high recyclability. Indeed, aluminum can be recycled indefinitely without losing its mechanical properties. This reduces both the demand for raw materials and the carbon footprint associated with the production of new materials. The aluminum recycling process also consumes much less energy than the initial production process.

At a time when natural resources need to be preserved, aluminum is a sustainable, environmentally-friendly choice for manufacturers.

HALCYON’S ACHIEVEMENTS

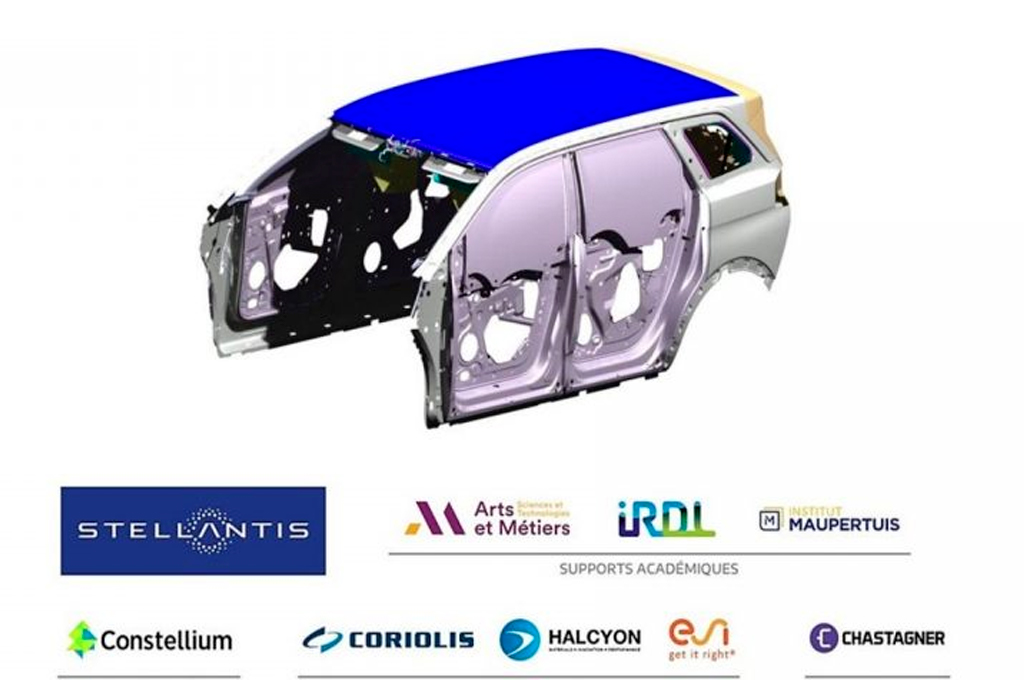

Design and manufacture of a lightweight, high-performance roof panel

As part of the AM2 Consortium led by Stellantis, Halcyon designed and manufactured this innovative roof panel. This solution reduced the weight of the structure by over 50%, while maintaining equivalent performance and guaranteeing total recyclability. What’s more, this part is perfectly suited to mass production.

Development of a cooling floor for the electric Apine

Valeo and Renault Sport called on Halcyon to design and produce the small production runs of the cooling floor for the electric Alpine. The cooling system was integrated into the sandwich panel, with compartments for the batteries.

Creation of a revolutionary car rim

Halcyon has designed and manufactured an ultra-light, recyclable rim. Thanks to its lightness and robustness, this part won an award at MIDEST 2015.

If you’d like to find out more about our expertise and our ability to meet your specific needs,

the HALCYON team will be delighted to hear from you!