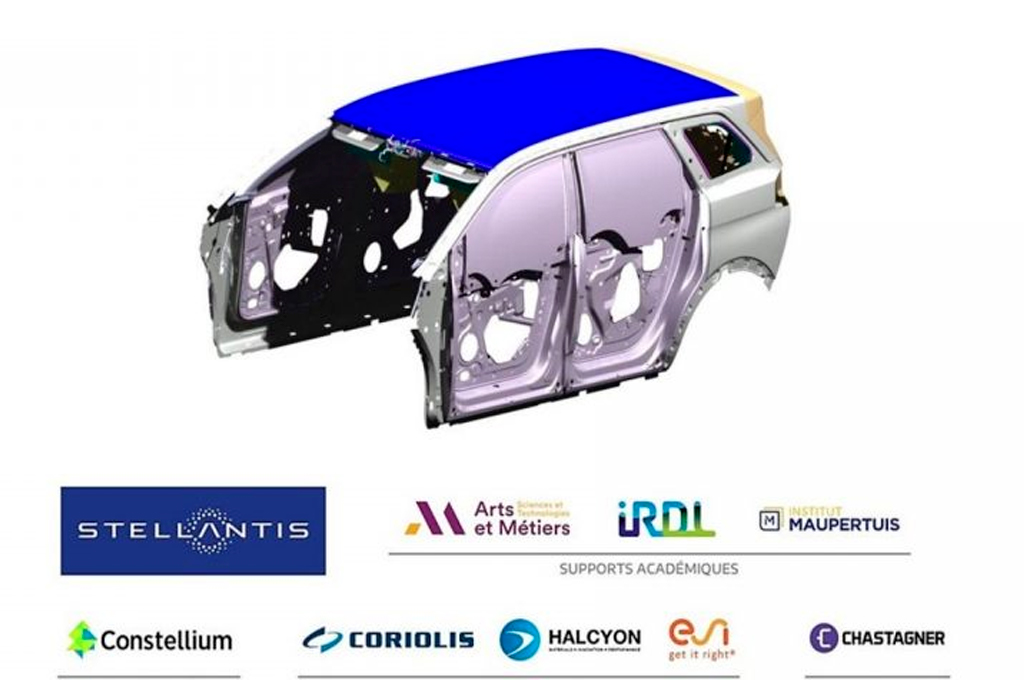

HALCYON, EXPERT IN THE FIELD OF COMPLEX ALUMINUM HONEYCOMB SANDWICH PANELS

From design to industrialization, we adapt our aluminum sandwich technology to your technical parts.

The advantages of aluminum honeycomb sandwich structures:

- Reduced mass for identical mechanical properties

- Reduction in raw material losses

- Recyclability of aluminum

- Innovation for 3D parts with complex shapes

- Process adaptable to small, medium and large series

HALCYON INNOVATION

Widely used in the transport industry, honeycomb parts consist of 2 skins with good mechanical properties, and a lightweight core. These 2 materials combine to produce lightweight structures with excellent mechanical properties.

Until now, this technology was limited to simple, flat parts. But now, thanks to Halcyon’s patent, all part geometries can be adapted to this technology!

Thanks to our expertise in forming and machining aluminum honeycomb, we can produce complex parts to meet our customers’ needs. Whether cylindrical, conical or double-curved, we guarantee exceptional precision and quality, while optimizing part weight and strength. Our know-how enables us to adapt our production methods to the specific requirements of each project.

Today, Halcyon is the only manufacturer capable of forming complex sandwich panels with aluminum skins and an aluminum honeycomb core. This innovation offers an interesting alternative to fiber composites, as our material is recyclable and offers more competitive production costs.