TECHNOLOGY

Discover Halcyon’s sandwich panel technology and expertise.

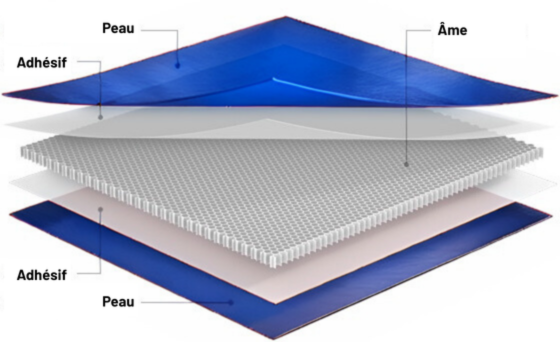

What is a sandwich panel?

A sandwich panel is a multi-layer composite material designed to offer an optimum balance between lightness and mechanical performance. It consists of two thin, resistant skins bonded on either side of a light but thick core.

The skins

Sandwich panel skins provide tensile and compressive strength. Their material is chosen according to the performance required.

At Halcyon, we mainly use aluminum for skins, a material that offers an excellent strength-to-weight ratio, good corrosion resistance and easy shaping. This choice guarantees both mechanical performance and lightness, while ensuring compatibility with our aluminum honeycomb core.

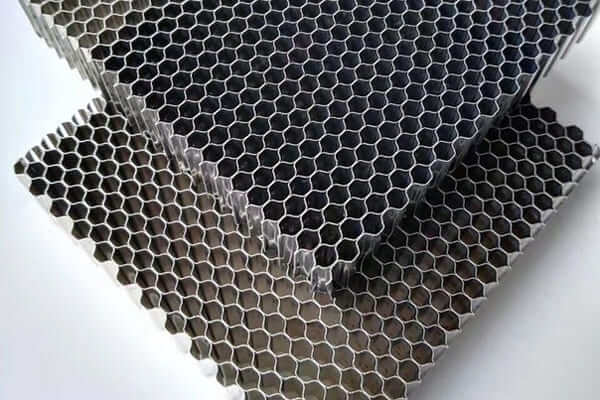

The core

Placed between the two skins, the sandwich panel core plays an essential role in the structure’s overall performance. It can be solid or hollow, as in the case of honeycomb structures. Its main function is to maintain a constant distance between the skins and transmit mechanical forces by shearing. By increasing the moment of inertia, it considerably enhances the panel’s rigidity while keeping its weight to a minimum.

At Halcyon, we have perfected the use of aluminum honeycomb core, a solution that is both light and resistant, and perfectly suited to the most demanding technical applications.

Adhesives: the invisible but essential link

The performance of a sandwich panel relies heavily on the quality of the assembly between its components. High-performance structural adhesives are used to bond the skins to the core, ensuring even load transfer and long-term durability. These adhesives must offer excellent shear and peel strength, while being able to withstand demanding environments. At Halcyon, we select and apply the adhesives best suited to each application, playing a key role in the integrity and functionality of our panels.

Integrated functionalities

In addition to its mechanical properties, the sandwich panel can be designed to meet other functional requirements: energy absorption in the event of impact, thermal insulation… The choice of skin and core materials thus enables an “integrated” approach, combining structural performance with specific functionalities according to specifications.

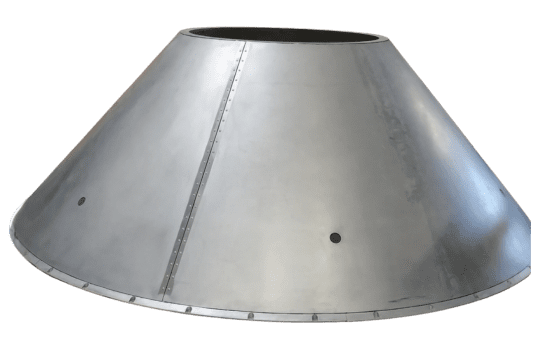

Halcyon innovation: complex shapes made possible

At Halcyon, we push the limits of sandwich panels thanks to a unique patented technology. Our innovation makes it possible to manufacture aluminum honeycomb sandwich panels with complex shapes, without compromising on mechanical performance or lightness. This breakthrough opens up new prospects in demanding sectors such as aeronautics, defense and transport, where the combination of unconventional geometries, high rigidity and low weight is crucial.

This exclusive process reinforces our ability to meet ambitious specifications by offering tailor-made solutions combining functionality, performance and innovation.

Learn more about technology applications