Halcyon & space: expertise for lightness

Reaching Further, Lighter… and More Sustainable

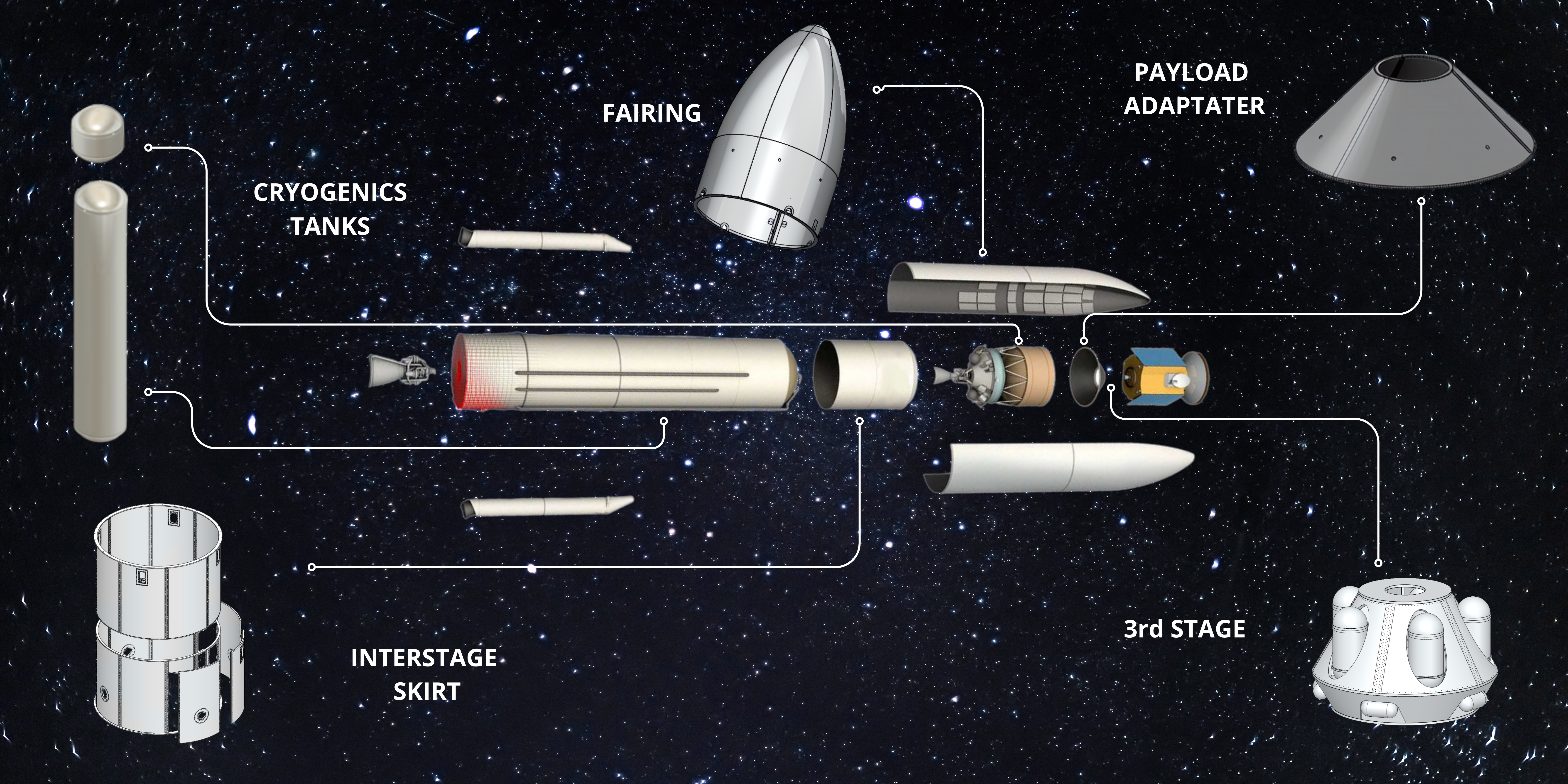

In the space industry, every ounce matters. To meet the growing demands for performance, reliability, and sustainability, Halcyon offers a unique structural technology: aluminum honeycomb sandwich panels—lightweight, strong, and adaptable to the most complex shapes.

Designed for launchers, satellites, and onboard equipment, our solution combines mechanical excellence with a reduced environmental impact.

A customized solution for spatial structures

Our aluminum honeycomb sandwich panels are particularly suitable for :

-

micro-launchers

-

non-load-bearing subassemblies (secondary structures)

-

les équipements embarqués et charges utiles

Thanks to their rigidity, lightness and design flexibility, our aluminum honeycomb sandwich panels can be easily integrated into a wide variety of space applications, while guaranteeing performance and reliability.

Why choose Halcyon aluminum honeycomb sandwich panels?

-

Maximum lightness: optimized structure for reduced weight

-

Excellent mechanical resistance: withstands vibrations, shocks and thermal stresses

-

Durable and recyclable: a responsible choice, designed to last… and be reused

- Lower production costs: affordable raw materials, reduced manufacturing time

100% mastered industrial know-how

At Halcyon, we design, manufacture and test every part to the highest quality standards:

-

Precise drawing of aluminum honeycomb

-

High-performance aluminum machining

-

Gluing on complex shapes

- Custom assembly

-

Laser inspection of parts, tools and assembly

In-house tool design: precision made to measure

We design and manufacture our own tooling in-house, so that we can tailor every part to the shape and function required, without compromising on precision. This total control enables us to :

-

Quickly react to specific needs

-

Produce single parts or small series with very high precision

-

Adapt our tooling to each customer’s geometry and constraints

Thanks to this tailor-made approach, we can optimize every manufacturing step, while guaranteeing high levels of quality and repeatability.

A collaborative and flexible approach

We collaborate with your teams right from the design phase to develop parts perfectly adapted to your constraints. Our agility enables us to deliver quickly, with a high level of precision and quality.

Got a space project on the go?

Contact our team – we’re ready to get on board with you.