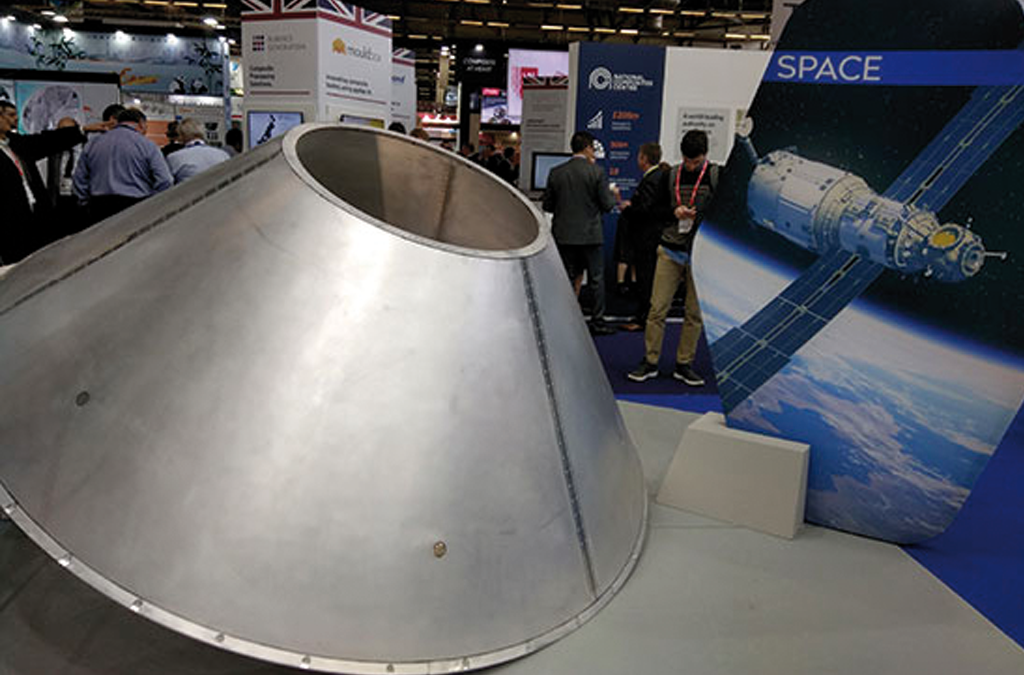

Halcyon has recently designed an aluminium honeycomb payload adapter for the space industry. This conical structure acts as an interface between satellite and launcher.

Halcyon has developed with the CNES (French National Center for Space Studies), an aluminium honeycomb payload adapter. The intention was to compare Halcyon’s technology with the existing carbon-fiber cone. The payload adapter featured is made of 1.5 mm-thick aluminium sheets and a 30 mm-thick aluminum honeycomb.

First, Halcyon’s solution presents a 15% weight saving compared with the existing solution, with the same mechanical properties (stiffness, high resonance frequencies, buckling, tension and compression). For the space industry, improving the mass of a part means extending the satellite’s service life: the satellite’s lifetime in space is extended.

Another benefit of the aluminum honeycomb structure is its economy: raw materials, manufacturing time and production costs are significantly reduced. Whether for prototyping or mass production, sandwich structures are more affordable than carbon fiber composite parts.

The featured part was produced using Halcyon’s patented aluminum honeycomb forming know-how. Double-curvature parts are possible thanks to aluminum honeycomb forming and an aluminum skin forming process.

If you wish more information about our knowledge and ability to meet your specific needs, the Halcyon team will be happy to answer your questions!